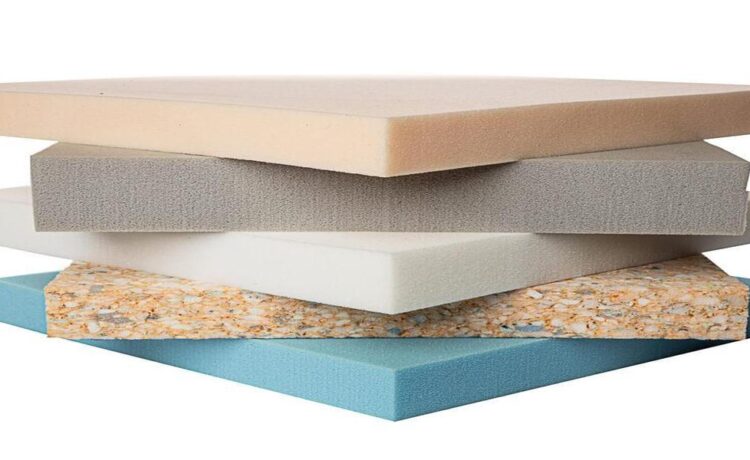

Choose the right type of foam: There are different types of foam filling materials available such as polyurethane foam, memory foam, latex foam, etc. Each type has its unique properties and benefits, so make sure to choose the right one for your needs.

Measure correctly: Accurately measure the area you want to fill with foam. Make sure to measure both the length and width of the space to determine the amount of foam you will need.

Prepare the space: Before filling the space with foam filling, make sure it is clean and free of debris. This will ensure the foam adheres properly and is evenly distributed.

Use the right tools: Foam filling can be messy, so it’s important to use the right tools to make the process easier and more efficient. A foam gun, for example, can make it easier to apply foam evenly and avoid excess waste.

Don’t overfill: It’s important not to overfill the space with foam as this can cause the foam to expand and potentially damage the surrounding area.

Allow time to cure: Once the foam is applied, it will need time to cure and fully expand. This can take anywhere from a few hours to a few days, depending on the type of foam and the environment.

What Is FOAM FILLING and How Does It Work?

FOAM FILLING is a process that involves injecting a liquid foam into an object to fill any voids or gaps within it. This foam can be made from a variety of materials, including polyurethane, epoxy, or silicone.

The foam-filling process begins by drilling holes into the object that needs to be filled. These holes are strategically placed to ensure that the foam can reach all the necessary areas. Once the holes are drilled, the liquid foam is injected into the object using a special injection nozzle.

The foam then expands and hardens, filling in any gaps or voids within the object. This process can be used to fill a variety of objects, including tires, boat hulls, and even buildings.

Foam filling has several benefits, including increased durability and stability of the object, improved buoyancy, and improved insulation. It can also be used to reinforce structures, reduce noise and vibration, and even provide fire protection.

Want A Thriving Business? Focus On FOAM FILLING!

If you are interested in starting a business focused on foam filling, here are some tips to help you thrive:

Develop expertise: Learn everything you can about the foam filling process, the types of foam available, and the equipment required to perform the job effectively.

Establish relationships with suppliers: Find reliable suppliers of foam and equipment and establish strong relationships with them to ensure a steady supply of materials.

Focus on quality: Ensure that your foam filling services meet or exceed industry standards and customer expectations. This can help you establish a positive reputation and gain repeat business.

Offer competitive pricing: Research the prices of other foam-filling businesses in your area and develop pricing strategies that are competitive but still profitable.

Promote your business: Use online and offline marketing strategies to promote your business, such as creating a website, social media presence, and attending industry trade shows.